Marauder

Pistol EVP |Benjamin

Discovery EVP

NEW!!

Projects "BLOG" Current projects and prototyping discussions

Crosman Pistol PCP Conversion Tutorial - (Email for link to tutorial)

NEW!!! TKO Productions! Crosman 2240 Teardown Videos on Youtube.com

Part

1 (Teardown) 10:00: http://www.youtube.com/watch?v=pTHChcW9ktI

Part

2 (Assembly) 10:00: http://www.youtube.com/watch?v=QuGSaO_B_gU

Part 3 (Assembly) 4:00: http://www.youtube.com/watch?v=Wp245fjsCus

(Not

sure why the volume is so loud....)

This

page will always be under construction!

Because

I actually shoot each gun for accuracy (18 yards) and velocity (Chrony)

when one comes in for a tune, I can plot to what effect each modification

has on the overall performance of your airgun.

Here

is what I have found:

For accuracy

#1.

Fix the barrel band. Probably the easiest way to maintain accuracy

from session to session.

The barrel band has 2 set screws that are, in effect, squeezing

the barrel and airtube together. Since the band is "split"

at the juncture, the band spreads apart as the set-screws are tightened.

The tighter they are, the more the barrel is pinched towards the

airtube. You can see this effect if you sight down the barrel and

look at the space above the barrel and below the airtube. (You probaby

won't be able to see the gap under the airtube unless the action

is out of the stock. You will also see this on all current Crosman

guns that use the barrel band.)

This squeezing causes two problems:

#1: The barrel is being tensioned downward. If you

slip the barrel band off the action, you will notice that the barrel

is actually angling upward, away from the airtube. That is because

the design of the Crosman breech port seal and the tiny forward

breech screw act as a pivot point while the rear action screw is

of a much more stout construction and acts as the lever.

#2: The Discovery is a great gun, but a little loud. The addition

of a muzzle brake makes the gun more pleasant to shoot at home,

etc. The smaller .75" brakes I and others make allow the filling

of the gun while installed, but that downward angling barrel can

cause it to be a very tight fit for the fill adapter. Hence setting

up the gun with a parallel barrel helps while filling the gun.

We can see that clamping the barrel parallel to the airtube is the

desired effect, but the design of the band doesn't allow that if

the screws are tightened securely.

Shimming

the barrel band… Shimming

the barrel band…

The quick and dirty solution (and one that works quite well), it

to cut two (or more depending on the amount of distortion our band

has) 1/2" X 1/2" pieces from a soda can. Form one piece

to the curvature of the diameter of the barrel, and the other to

the curvature of the diameter of the airtube. With the barrel band

set screws loose, slip the 1st piece UNDER the barrel, between the

barrel and the barrel band, and the other piece OVER the airtube

between the airtube and the barrel band. Then tighten the set screws.

Since the barrel band is "split", overtightening the set-screws

will cause the same tensioning problems.

Drilling

for additional barrel set-screws… Drilling

for additional barrel set-screws…

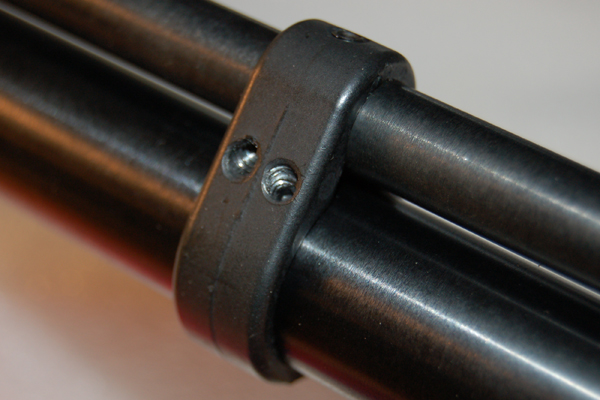

A bit tougher but much better method to adjust the barrel is to

drill the barrel band and install additional set-screws.

This makes a "3-point" cradle for both the barrel and

airtube and offers a much better and sturdier attachment. This is

the method I use when I build a gun based on the Discovery and am

looking for ultimate accuracy with the factory barrel. Here's a

picture of one that has been drilled with set-screws added. Two

holes angle upward and two holes angle downward. I used 6-32 set

screws and sightly grind the points off the screws to avoid scarring

up the airtube. I don't want to cause any gouges where a stress

crack may develop. (Cranking down on the factory set-screws will

already have scarred up the airtube.)

It's tricky to drill the flat at an angle. I use an end mill and

do a litte side cut flat then drill with a #36 bit. You can do it

in a drill press. Make a small dimple at the desired points, then

angle the band and drill your angle.

#2: Smooth the leade-in ("chamber")to

the barrel. We are trying to achieve a nice, smooth transition

of the pellet into the rifling of the barrel.

I have not found any difference in accuracy from a

barrel that has a very long angle to the rifling compared to one

that has a sharper transition, but fine accuracy from a crosman

barrel always requires that the pellet head be seated in the rifling

to eliminate any yaw being intorduced to the centerline of the pellet

compared to the bore of the barrel.

I use a tool I made that has a collar depth gauge

to prevent cutting the leade too deep. While the barrel is in the

lathe, I take off about 001 from the face of the breech end of the

barrel for a tighter lockup of the bolt handle.

#3:

Recrown the barrel. I have factory crowning on barrels

from Crosan that were far far off center. Not all crowning is bad

from the factory, but I would say 85% of the barrels can be improved. #3:

Recrown the barrel. I have factory crowning on barrels

from Crosan that were far far off center. Not all crowning is bad

from the factory, but I would say 85% of the barrels can be improved.

I cut the barrel flat, then cut a 11 degree inset,

and lap with a brass lap and 1500 grit wet-dry sandpaper soaked

in thread cutting oil. I run the lap both clockwise and counterclockwise

7-8 times, always ending with the barrel spinning clockwise (reverse

from usual lathe turning direction.) A cotton swap in the muzzle

pulled out slowly tests for burrs.

#4 Lap the barrel. I concentrate

on lapping the first 2/3rds of the barrel, with a quick final lap

of the entire length. I'm trying to keep the barrel from scouring

any lead from the fine pellet skirt.

More to come!!! |